Their last build, this 1992 Yamaha YZ125, is a cracker and Kane and Pete have stuck at all four builds for three years. They sourced parts from all around the world and the perfectionist in Kane and Pete meant they often had to rebuild one part numerous times. Kane never complained, gave up or settled for average, in fact, he often held his dad accountable for the quality control they hold so high.

So what went into this last build and has it changed Kane’s life? Let’s find out.

ADB: Why rebuild a 1992 Yamaha YZ125?

Peter Johnson: Well, the reason we restored this bike was to complete the set of 1992 125cc two-stroke motocrossers.

ADB: Was it the hardest of the 1992 range to source? Why was it last?

Peter Johnson: Not really, we did have a couple of options when we were looking to purchase this bike, although this one was in the best condition and priced reasonably well at $4700.

It wasn’t a bike we were particularly keen on the style of, so I reckon that’s why we kinda left it until last. But in hindsight we probably should have keep our favourite bike until last. That’s because we got better as we got further into our builds and found little tricks to make older parts look even better. So in saying that, this is probably our best quality build.

ADB: Is there a particular model that you and Kane have both preferred to build and look at?

Peter Johnson: Well for me it’s the Suzuki RM125, I just appreciate the courage of Suzuki going with such an extravagant design, which we think is an icon now.

Kane Johnson: For me it’s the KX125, I love the blue anodised forks, the radiator shrouds that wrap around the tank, the graffiti graphics and the overall shape.

ADB: Did you buy this bike during COVID as well?

Peter Johnson: Yes this was another COVID-inspired bike. I’m not sure you could call it a contactless purchase though… [laughs].

ADB: What condition was the bike in when you bought it?

Peter Johnson: We actually picked this bike up at a servo on the Hume Highway, so we didn’t ride it at all, I just started it. It was in real good condition. We did notice a bit of damage to the swingarm, exhaust chamber and a few other minor issues but the main things like frame, rims, forks and engine all looked okay.

ADB: When you got the bike back to your shed, what were some of the major problems you found?

Peter Johnson: So the swingarm had obviously had a decent hit as the right side had a big dent below the caliper, the exhaust chamber had some decent damage as well as some very ordinary welding to patch it up. The tank was scratched up and had some yellowing, which we know from the CR build that it’s near impossible to rectify (luckily Clarkes have an aftermarket tank for this model).

We also spotted that it looked like the clutch casing had a repair made. This wasn’t the case and it was just scratched up pretty bad from the brake pedal. All-in-all we were pretty pleased with the overall condition but you’re right, you can never really tell until you start pulling things apart.

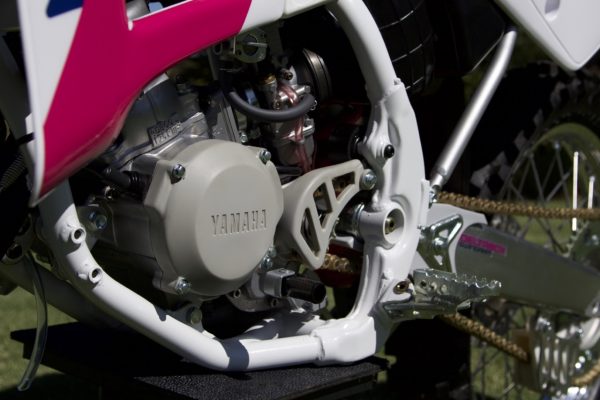

We decided we would paint the frame ourselves and the money saved we would spend on an aftermarket tank, we know how hard white tanks are to restore (even then we might not be happy with the outcome). We’ve kept the original tank and maybe one day down the track it’ll get the treatment. Some of the smaller plastic parts on this bike took a lot of sanding and polishing work, the magneto cover took around eight hours.

ADB: What was the hardest thing to fix?

Peter Johnson: Look, probably the hardest thing to restore on this bike was the exhaust chamber. It had some pretty hefty dents and some ugly welds but between Dean from Dynabuilt and our trusty two-stroke pipe repair kit (bought from Ebay) we don’t think this particular pipe could look any better.

I must say though if you’re going to use these repair kits, take care it’s a lot of heat and a lot of air pressure.

ADB: What was the most important thing to get right on this particular Yamaha YZ125?

Peter Johnson: For us the most important thing cosmetically was the engine casings, seat alignment, margins, swingarm detail and well, we could go on and on. Pretty much everything gets the royal treatment (even parts that are never seen).

Function-wise, everything has to be rebuilt to as good, if not better, than standard, all four bikes have every moving part rebuilt. You could grab any one of the set, put some fluids in, and go for it.

ADB: Was this bike a complete strip down and rebuild like the others?

Peter Johnson: Yep this bike, like the others, is a full nut and bolt resto

ADB: Who did the work for you?

Peter Johnson: It’s funny over the builds you find out which mechanics, repairers, services suit you the best. It kinda doesn’t matter too much if price is a little higher, if you put this much time in you just want the best possible job.

I won’t mention his name, but we had a powder coater early in the piece which we returned a part we weren’t happy with and he carried on like we were being too picky. Four hours had probably gone into this part just preparing it for powder, he redid it but that was the last time we used him. Our list of preferred businesses is in the starburst.

ADB: Did the motor need a complete rebuild?

Peter Johnson: Yeah this one also got the full rebuild from Dave at DM PROBIKES his knowledge on motorcycles is second to none. The engine was a runner like the others , but to be safe and for peace of mind they’ve all been freshened up

ADB: Do you know any history about this particular bike?

Peter Johnson: Not really, I just know the guy we bought it off had, I think, three of these bikes and this was the second best in his fleet.

We know, like all four bikes, that the engine and frame numbers match up, which we haven’t spoken about before but that has been very important to us. A lot of bikes this old are Frankenstein’s. But we’re pretty happy knowing we have matching numbers.Knowing what is original or not is probably something we’ve learnt over the years, but a lot of parts have a number, stamp or brand on them, we also look at a heap of pictures online.

ADB: Was this build different to the others?

Peter Johnson: To be honest they have all been pretty similar, I suppose being the same year make every manufacturer was on the same page with technology, they all had upside forks. The only thing that varied a little was the swingarm linkages and frame shapes, oh the KX125 had a tank hidden behind the radiator shrouds, which does take care of a tank resto.

ADB: If you had your time again with all the builds, would you do anything different?

Kane Johnson: Yeah we probably would’ve changed the order of builds. My favourite is the KX so I would’ve liked to do that last. We would’ve got a spray gun earlier as it was a lot easier and a lot more consistent finish than a two-pack aerosol can.

ADB: Kane, has it inspired you to get into being a bike mechanic or doing more rebuilds on his own?

Kane Johnson: I would definitely love to do more builds in the future, I felt it kept me occupied in the lockdown period. I’m a bit more busy now with work and don’t have much time on my hands but would love to do one of my own down the track.

ADB: Kane, what was the greatest thing you learnt from all four builds?

Kane Johnson: I’ve learnt that things take time and not to rush anything, if you want it perfect, you need patience. Preparation is the key.

The swingarm on this bike obviously copped a heavy hit as there was large dent just below the rear caliper. Again, Dean come up with the idea of drilling a hole on the inner side of swingarm so we could use a punch to knock out the dent, then only a small amount of TIG was required to close the hole.

Pete’s Preferred List

DYNABUILT

DM PROBIKES

WESTERN METAL POLISHING

COBURG PLATING

COLLINS ANODIC TREATMENT

SQUARE ONE FACTORY