This is the story of a custom bike build of two separate Hondas, a CRF250L rolling chassis and a CB500X engine and electrics.

No matter what your preferred style of riding, there is a bike these days to suit you. I would go so far as to say that used within their design parameters there are no bad bikes these days. As a wise man once said though, you can’t please all of the people all of the time. He was probably a dirt bike rider.

Due to the market being swamped with choice we rarely see any home engineered hybrids anymore. I’m talking about a unique blending of parts from different bikes to make one complete but totally unique bike that operates like it came from the factory. I’m not talking about your mate down the road who has loaded up his bike with anodised bling that does sweet fanny adams for performance.

Many adventure riders are of the opinion that the manufacturers have left one hole unplugged in the market. They have long dreamed about what to them is the perfect adventure bike. They envision a bike that is light in weight, with a mid capacity twin cylinder motor to make long unavoidable stretches of slab more pleasant, good fuel range and an absence of what many of them regard as unnecessary electronic widgets. Amongst these types such a mythical bike is known as the Unicorn.

Being of an adventurous nature, a handful of people on the Adventure Rider web forum (advrider.com) have adopted the attitude of “if the factory won’t build it for me, then bugger it, I’ll do it myself”. Several such Unicorns have been built to date in various back sheds around the world combining Honda parts. We thought we’d look at two of them, one in California built by Levi Harris and the other in Surrey in the UK put together by Andy Scutt. These bikes are the same but different, in that they combine the same major parts but have some slight personalised differences in the actual build.

These two Unicorns are the product of a possibly incestuous marriage of two separate Hondas, a CRF250L rolling chassis and a CB500X engine and electrics. The result is just what many that are on a quest for their own personal Unicorn are actually looking for. Levi’s bike came in fully fuelled with a wet weight of 158kg and Andy’s at 153kg. He also gets 305km from the 12.5l Acebis tank. We have a shed full of questions about these builds and we thought we’d investigate further so we asked the following.

What inspired you to build the bike?

Levi

I wanted the romance and the punch of the old Dakar rally bikes, along with the ease of use of a modern power plant and chassis, and I wanted it to fit me.

Andy

I couldn’t find a bike that delivered both off road and on. I tried light off road bikes but they were terrible on the long road sections, high on maintenance and struggled to carry luggage. More road focused bikes were just too heavy off road, ruining the fun part and limiting the type of off road I could ride. I made a check list of the type of bike I wanted. It was a long list and I very quickly realised that no bike ticked all the boxes. During my search, I came across a CRF500L build on ADVrider forum. That first bike was very rough but it ticked all the boxes so I started my own build with a more factory-finish version in mind, like something Honda themselves would build.

Why did you choose to go with a Honda frame and engine, did you consider other makes/combinations?

Levi

The CRF250L fit me pretty well and as a parts bin bike there’s lots of Honda parts that play nice together without tons of adaptation.

Andy

I had ridden the CRF250L and it’s such a fun simple dual sport bike. It has a steel frame, a good sub-frame and it had a pedigree of surviving around the world trips. I just didn’t like the engine that much. I also went to see John from Rally Raid Products to ride his RR CB500X, which I thought had a great engine but terrible ergonomics for off road riding and was too heavy. Combining the 2 seemed the obvious choice. Also, keeping it all Honda meant I could still get support from any Honda garage.

Why a 250 frame and not a XR400 or 650?

Levi

The 250L is current, steel (easy to work with) and has a healthy aftermarket of choice parts available. Also, the 250L mill is huge for what it is. It’s a massive engine for a 250 and the frame has an equally huge hole in which to stuff much better engines.

Andy

Here in the UK the CRF is the only currently selling dual sport bike and I really wanted to build an as new a bike as possible. The 250 frame is steel and therefore easy to get welded anywhere. It has a strong removable sub frame and is just wide enough for the 500 engine as the 250 engine is a bit of a porker.

What were the biggest obstacles to overcome?

Levi

None really, I knew it would work and work well. This actually wasn’t the first CRF500L. A guy in Canada and I had a lengthy dialogue about the possibility and I did my best to convince him to try it first, which he did. But I felt like the execution could have been better. So, I tried not to rush it and find more elegant solutions to stuffing the 500 in there.

Andy

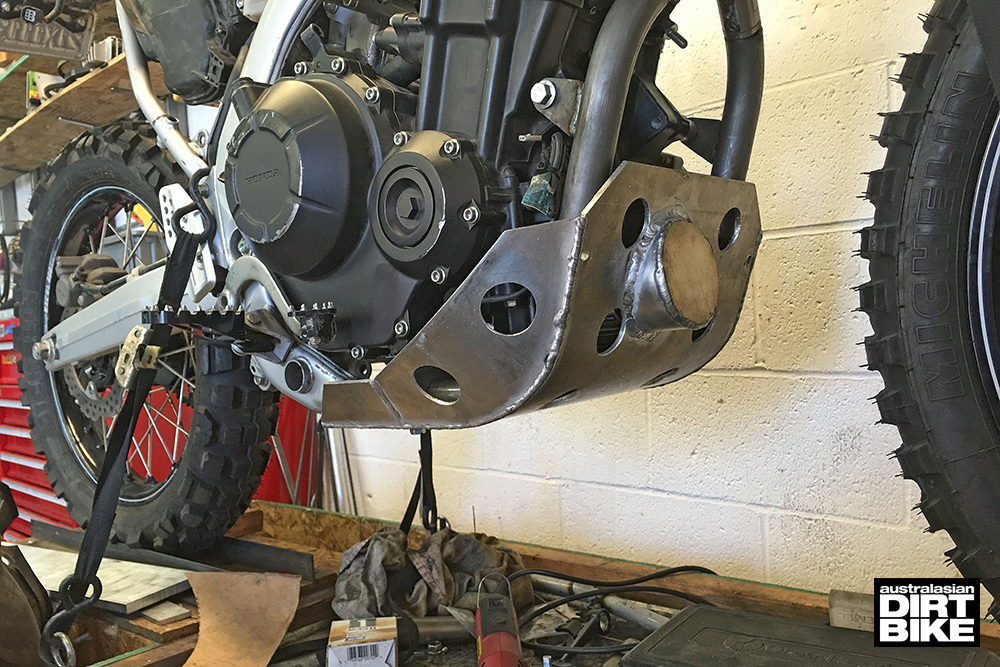

The frame cuts were daunting, the engine cradle needs to be cut out and enlarged and I fitted lap joints in the new cradle to make it easier to get the new engine out. The loom was also a chore, my background is in electronics but it is still a big task to alter a loom from one shape bike to another. We now refer to it as the loom of doom!

How difficult was it altering the frame?

Levi

Easy, any competent fabrication shop could handle it. Mind you there are some critical fitments but nothing heroic to pull off.

Andy

As I mentioned, the engine cradle or rails had to be cut out and new engine mounts fabricated. Additionally a little of the headstock (above where the cradle was cut out) was lapped out to give a bit more room. To be fair, the engine fits in pretty well.

What about centralising the motor in the frame left to right and lining up the sprockets, how difficult was that?

Levi

Easy, the engine lines up on centre with a machined sprocket and some spacer magic in the rear hub.

Andy

Amazingly that was quite easy, there isn’t much difference in width of the 2 engines, as I said, that 250 is a bit fat compared to other 250s

Are all the parts from Honda or did some need to be fabricated?

Levi

All the major components are Honda parts. The headers, sump and skid plate are custom jobs and the frame takes some modifying but it’s mostly off the shelf Honda parts.

Andy

The goal was to keep it as Honda as possible but I did need to some fabricate some parts. The engine mounts, the dash holder, bash plate, exhaust and the air intake are all custom built.

What wheels did you use?

Levi

I built the wheels. I used a 250R front hub and a XR650R cush hub and shimmed out the carrier to correct the chain line. The chain line correction is tiny so you can replace the rear wheel or just live with it. But why not build some pretty sparkly wheels?

Andy

Originally I went with the standard 250L wheels but I then swapped the front end over to 450X forks, brake caliper and wheel. The rear is still the original with no cush drive. Trying to find a balance between travel range and off-road climbing torque I ended up with 15/42 gearing.

How did you make the intake manifold between the throttle bodies and airbox?

Levi

It’s just a simple aluminium manifold. I was really happy with how it turned out. The joiner is right between the upper and lower sides of the manifold and it hinges on the lower sub-frame bolts. So you just take the upper sub-frame bolt out and loosen the joiner and the whole thing separates and pivots back on the sub-frame. Once you get that out of the way, the throttle body is accessible and can be removed without dropping the engine.

Andy

It’s a tight space to fit through the frame so I got a local fabricator to hand shape me the intake, he did a brilliant job.

Was any modification required to the airbox?

Levi

Just at the front where it bolts up to the aluminium manifold. I played with different openings and changing the volume but as it turns out a 250 single doesn’t have that much different a requirement to a 180 degree twin. The normal “cut out the top on the lines” that Honda provides you with is just perfect. Quiet too!

Andy

The only change I made was to fit a Unifilter filter and cut out the snorkel. It seems to breathe well enough plus the changeable skins on the Unifilter are very handy.

Did you use the brakes from the 500?

Levi

I used CRF250SM brakes which are larger. I believe the rally version currently available has the same brakes but those weren’t around at the time.

Andy

No, I have the original 250 rear brake and upgraded to a CRF 450 brake on the front. The insurance company engineer insisted on bigger brakes.

What forks and shock did you use?

Levi

Racetech, as the CRF250L suspension out of the box left a lot to be desired. The shock overheats quickly and the back gets loose. The forks were just perfect for Barbie but I slammed through the stroke with such repeatable predictability that something had to be done. The Racetech emulators, springs and shock are the only way to go. It took a couple of rounds of complete disassembly and experimentation to get it perfected but it was well worth the effort. Later I replaced the forks completely with 450X forks with custom everything but I never did I get them dialled in like I had the original forks.

Andy

The front is OEM Showa 450X forks with up-rated springs and I have a YSS shock. Originally I had a 250L Ohlins shock but when I changed the front end I wanted the longer travel 250 Rally rear shock which is 1″ longer but the Rally Ohlins is eye wateringly expensive. The YSS shock works really well for about half the price.

Where there any problems with the electrics to be overcome?

Levi

Oh yeah. That’s where you guys need to pay close attention. You need an ECU, ignition and instrument cluster from North America. All the others have Honda HISS (Honda Ignition Security System). You cannot win with HISS. Even if you managed not to piss off the system and manage to get the whole thing working on the new bike, if something happens, Honda will not reset it. And there is nothing you can do with it as an end user. The harness isn’t too bad to modify to the CRF controls but it’s more than an evening of work.

Andy

The “loom of doom” was a challenge but, other than that, I’ve had no real problems. It’s probably because I stuck with Honda as much as possible. I used a USA loom, ECU and dash mainly because every UK CB has HISS ignition and ABS. I didn’t want either of those for simplicity.

What instrumentation do you have on the bike, speedo etc?

Levi

All the stock Honda display functions still work. It’s just the normal 500 display.

Andy

It is a standard CB500X dash, plug and play once we’d fabricated a mount for it. The electronics, ECU etc. are all from the 500 or aftermarket 500 upgrades.

Is the motor standard?

Levi

Mostly, it’s got a power commander because, why not? The oil pan takes some attention to fabricate but it’s very simple. The hardest part is keeping everything clean while you have the crankcase open. I built a twin exhaust system, for both the look and the sound.

Andy

100% standard, it’s a cracking engine, butter smooth and so much more power and torque than the 250, it climbs like a mountain goat. On the road you can sit at 75mph (120.7kph) all day long, vibe free. I used a two into one exhaust system, which is the standard design on the 500 purely to save weight and I missed my 150kg target by 3 kg. The brochure claims 147kg for the 250 and 197kg for the 500.