The two-stroke versus four-stroke argument has been around since JC played fullback for Jerusalem. Four-strokes gradually took over the market partly due to the world wide desire counter the effect of flatulent bovines hell bent on destroying the planet, and possibly due to higher repair costs being of benefit to manufacturers. The exhaust emissions has always been a negative point for two-strokes but the positives were more power, lighter weight, simpler design and easier maintenance. If you want to ride a two-stroke motocrosser these days your options are severely limited but that may not be the case any longer thanks to TSR and the mighty Honda CR500.

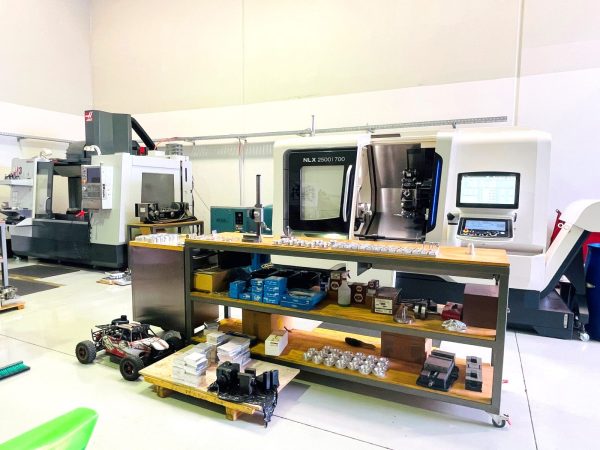

Troy Spencer and his wife Melinda run , an engineering business on the Gold Coast and about seven years ago got into the market for modernising CR500 Hondas and over time have expanded to include CR250’s and KX500 Kawasaki’s as well. They can breathe new life into these old school two-strokes and help keep them both running, and more importantly competitive.

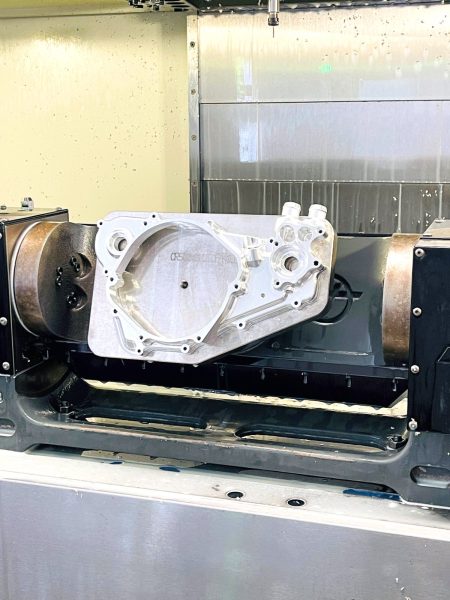

I’ve long been fascinated by “Frankenbikes”, the marrying of different engines and frames together since seeing a Husqvarna frame with an XL250 Honda motor at the Pine View Pro Hart Desert Race in the late 70’s. What TSR offers is a chance to put a CR500 motor into a modern CRF450 alloy frame without a lot of the complicated fabrication work with engine mounts and frame alterations. This required a hell of a lot of time and study to come up with a workable plan but the proof is in the pudding and a straight engine swap is the result. Simply put, Troy produces new CR500 engine cases machined from solid billet alloy with the engine mounts in different positions, to fit the alloy frame.

It all started like so many good ideas as a one off machine Troy built for himself, as he’d always wanted an alloy framed 500. When he eventually decided to sell it, it sold instantly and he thought maybe there was a market for such bikes. Motors were easy to come by at that time, and relatively cheap so he started building complete bikes or rolling frames ready for the engine swap and they sold. Customers could also supply their own engine and Troy would fit it to a frame for them.

Originally Troy was altering frames but it was better to redesign the engine cases to be a straight up fit to reduce risks of frame failure as a large portion of the frame needed to be cut and realigned. No frame failures have occurred as a result of the conversion but a possible risk has been averted by redesigning the engine mounts on the cases and conversion time has been reduced as well. He still supplies frame kits for owners who want to do the conversion themselves.

As the supply of decent engines is drying up over time, this also prompted Troy to start producing his own cases from scratch. Also the quality of the engines being bought from overseas was not always as the seller had described it and was often suffering damage.

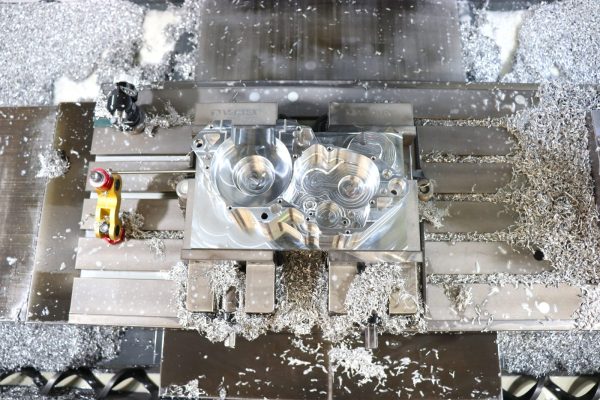

Over time the process has been modernised and streamlined and three five axis CNC milling machines are running full time producing engine cases. Each case can take from eight to ten hours to make and there are five separate operations per case but with only Troy and Melinda doing the work the quality control is exceptional. The set up time was substantial to program the machine, taking about 100 hours, but it only had to be done once, then the machine just keeps on producing parts from a solid block. The operator just has to remove the finished part and put a new block in for the next.

TSR has plans to produce more of the parts needed to keep these engines running well into the future and has hopes to eventually produce complete engines and fully converted bikes. A CRF alloy rolling frame fitted with either a 500 or 250 engine gives you all the benefits of modern suspension and handling with that old school two-stroke bark and bite. Currently about 70% of production is sold overseas to either the US or Europe. I can see desert racers in the USA having an obvious use for such bikes but I do wonder where the Europeans are riding them.

As the parts supply for these older engines will inevitably dry up as new parts are no longer made Troy has plans to make more of the internals than just the cases and other parts he currently does. In the future he hopes to be making crankshafts and gears as well and these will be all produced in house with the only outside work being heat treatment for parts such as gearbox internals. Just to keep things interesting there is also a plan to make parts for Suzuki LT500 quads which are popular in the US but have a problem with weak cases.

At the moment TSR produces engine cases, heads, clutch and flywheel covers, clutch housings, water pump covers and the water pump elbow for CR500’s all from billet alloy plus heaps of other parts. Being machined from billet also means the parts are stronger than factory castings and should tolerate wear and abuse a lot better. Similar parts are available for the CR250 and KX500 as well as billet power valve covers and titanium head nuts are available for all three models. TSR also has a range of parts for Yamaha and Tohatsu outboard motors if you happen to have a boat as well.

If you have a CRF with a blown motor and a large repair bill and access to a cheap CR500 or 250 engine then a conversion like this could be your answer. Get the relevant parts from TSR, spend a weekend in the shed with some cold tubes, some good tunes and maybe a mate for company and you’ll have your own unique ride that will turn heads even in the pits.

If you prefer green to red then TSR are planning another conversion for the KX500 engine with a bit more modernising adding a balance shaft as well as EFI and electric start and these should be available later in the year. That is a big effort just in design alone, with it taking about four weeks in front of a computer working out how to make everything fit. The end result is a big bore howling two-stroke that lets you finish your ride with all your fillings still in place and who wouldn’t love to ride something like that?

WORDS | WARREN JACK

PHOTOS | TSR