The hydraulic clutch versus cable clutch debate has been around since KTM began to introduce them in the late 90’s. By early 2000’s all KTM motocross and enduro machines were fitted with hydraulic clutches and the debate was as strong as ever.

In those early days when the kinks were still being ironed out there were plenty of cons against hydraulic clutches. The early hydraulic lines weren’t overly durable and susceptible to breaking or being torn and the seals in the master or slave cylinder often split. Those early systems used mineral based hydraulic oil and people would fill them with brake fluid causing the seals to swell and leak.

Twenty years later however the technology and design has been refined and the hydraulic clutch is much more durable and the cable versus hydraulic matchup is much more of a fair fight. So much so that we now even see the Japanese manufacturers now fitting hydraulic clutches on their motorcycles as standard equipment. Only the Yamaha and Suzuki are still persisting with the age old cable clutch design.

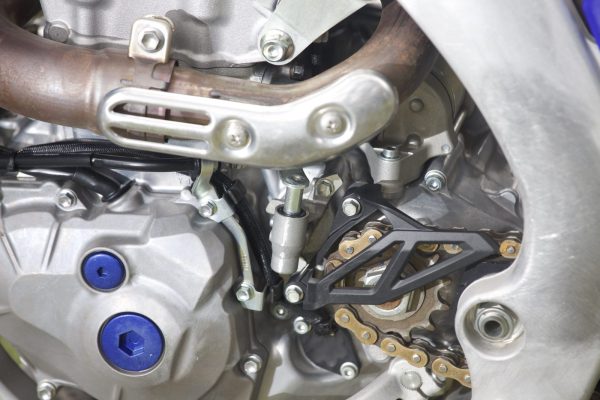

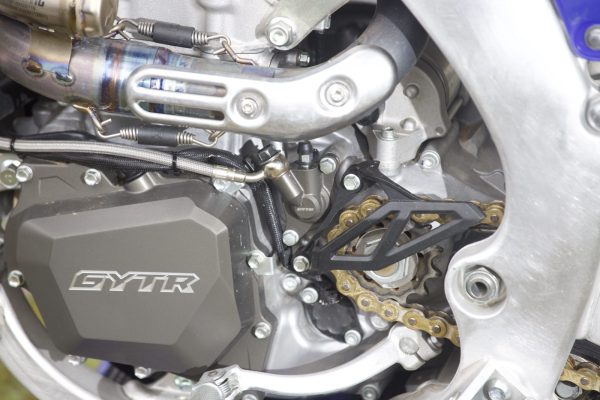

To settle the debate we took our Yamaha YZ450F long term test bike which came from the factory with a cable clutch and fitted up the GYTR hydraulic clutch system. Then we took a YZ450F of the same year model with a standard cable clutch and rode them back to back to get a feel for the two clutches and see what we preferred.

CABLE CLUTCH

There isn’t much left on the market that still comes with a cable clutch. I can only think of the YZ’s and RMZ’s.

Once upon a time, not to long ago, all the Japanese manufacturers swore by cable clutches and refused to change. Personally I think the biggest factor for the Japanese manufacturers hanging onto the cable clutch for so long is it is easier and cheaper to manufacture. These manufacturers are are out to make a profit and the best way is to make the bike as cheap as possible and sell it for as much as possible. Using a cheaper clutch is the best way to do that until the market demands for a hydraulic clutch for so long that you are forced to change and give it to them.

I was team cable clutch for a long time. I grew up riding bikes with cable clutches. Adjusting clutch free play was something I was used to and I felt like I had a more direct feel on the friction point on the clutch through a cable.

HOW DOES A CABLE CLUTCH WORK?

The design of the cable clutch is simple, a lever on the handlebar connects to a cable which runs to an actuator lever in the engine. You pull the clutch lever and the cable pulls against the actuator which either pulls or pushes on a rod lifting the pressure plate off the clutch pack allowing it to slip and free wheel. When the lever is released the springs on the pressure plate push it back against the clutch pack, crushing it together which causes the clutch to bind up and no longer slip.

Early cables were just wire running inside a steel sleeve and had to be oiled periodically or they would bind up. You would have to fit a cable oiler to the top of the cable and run lubricant down the cable until it dripped from the bottom.

Then they began to line the inside of the cable with a nylon sleeve which made the pull lighter as it had less friction. These cables required much less servicing. There are even teflon lined cables available that are even lighter again but lubricating them can damage the internal teflon lining.

The pivot point on the clutch lever matters. If the cable is mounted closer to the fulcrum point of the lever then the clutch will be lighter. It will also mean the clutch lever will have to travel further and the friction point where the clutch releases will be closer to the handlebar. If you move the cable mounting further away from the fulcrum point then the clutch becomes heavier but the friction point where it releases will be further away from the handlebar.

Changing the angle and length of the clutch actuator down at the engine has a similar effect. It was a common modification to cut the actuator in half and weld a piece in the centre to make the actuator longer which would in turn made the clutch lighter at the lever. Even where you place your fingers on the lever can have an effect on how heavy or light the clutch will feel.

PRO’S

- Cheap to manufacture

- Cheap to replace

- Can be modified or adjusted easily

- Direct feel through the clutch lever

- Reliable

- Easy to repair

- Easy to maintain

CON’S

- Cables can become frayed or dirty

- Cable can wear and become notchy

- Cable can break

- Cable free play needs to be adjusted as the cutch wears

- Cable free play needs to be adjusted as the clutch heats up

- Clutch actuator can become jammed with mud, dirt and rocks

HYDRAULIC CLUTCH

The hydraulic clutch came into the industry with a rocky start when KTM was breaking into the scene and there was a bunch of push back from the industry. The motorcycle industry is well established and anything new can struggle as we all prefer tried and tested technology. It took time for the hydraulic clutch to become established.

It took years for the old schoolers who grew up with cable clutches to fade out and the young ones who grew up with hydraulic clutches on 65cc minibikes to come through knowing nothing else. Early 2000 hydraulic clutches aren’t what they are today. They were much more susceptible to damage and nowhere near as reliable. The feel of them was quite spongey and vague and you never felt a direct connection with that friction point in the clutch.

Twenty years of development has been good to the hydraulic clutch and they now feel and operate just as good as any cable clutch, maintenance is minimal and failures are few and far between. I have to admit I never liked the hydraulic clutches of yesteryear. I was team cable all the way but in recent years with the refinements of the hydraulic clutches I have come around. Even the anti-hydraulic clutch manufacturers have started to see the light.

HOW DOES A HYDRAULIC CLUTCH WORK?

The hydraulic clutch system is reasonably simple. It is a sealed system filled with fluid, free from air. Fluid cannot be compressed but air can.

There is a piston in the master cylinder mounted to the handlebars that moves when the lever is pulled in. This piston pushes fluid along a hydraulic line to another piston in the slave cylinder in the engine. Because fluid cannot be compressed, the energy applied to the piston in the master cylinder travels through the hydraulic line and into the piston in the slave cylinder, moving it. This either pushes or pulls on the clutch pressure plate and releases the pressure on the clutch pack allowing the clutch pack to free spin.

When the lever is released the pressure on the piston in the slave cylinder is released. The springs on the clutch pressure plate clamp the pressure plate back onto the clutch pack binding the clutch back up so it doesn’t slip. Like the cable clutch, where you place your fingers on the lever will affect how heavy the clutch is.

Unique to the hydraulic clutch is the size of the piston in the slave cylinder. A smaller piston in the slave cylinder moves less fluid, making the clutch lighter but also moves the friction point of the lever closer to the handlebars. A larger piston moves more fluid but causes the clutch to be heavier and makes the friction point further away from the handlebars. Similarly the size of the piston in the slave cylinder down at the engine has similar effects.

These two piston sizes need to be tuned correctly to give the correct clutch action for the specific motorcycle. It is also important to note that some hydraulic clutches use brake fluid and others use mineral based hydraulic fluid. It is important you are using the correct fluid as the incorrect fluid will damage the system.

PRO’S

- Relatively maintenance free

- Smooth action

- No need to lube cables.

- Self-adjusting

- No need to adjust free play

CON’S

- Harder to repair

- More costly to repair

- More costly to manufacture

- Seals that can fail or leak

SO WHAT’S THE BEST?

This really comes down to personal preference. Jett Lawrence has been winning using a hydraulic clutch but Eli Tomac has also won a bunch of championships and prefers a cable clutch. There’s no such clutch that will make you a better rider.

I no longer like adjusting my clutch free play all the time and prefer the set and forget style of the hydraulic clutch. Younger me was a cable clutch fan but as the hydraulic clutch has improved I feel like I have just as good a feel on the hydraulic clutch and it is more consistent no matter how hard I push the bike or how hot I get the clutch. That’s really the number one thing that wins it for the hydraulic clutch in my opinion.

If we take a look in the enduro scene then I am 100% hydraulic clutch all the way. Have you ever been stuck on a hill giving your clutch a hard time and all of a sudden you start stalling it because your lever is all free play? Well I have and it’s no fun. You have to sit there while trying to not slide off the side of a mountain so you can adjust your clutch free play to going again.

There’s a million other things to worry about when you are out on the trails rather than your clutch free play. The last thing you want to be doing is adjusting your clutch every time you come to a hill climb.

JEFF BRIGGS ON THE YZ450F HYDRAULIC vs CABLE

This was a fun test and good to see the differences a clutch can make. Both clutches on the YZ’s are relatively light but you definitely notice the hydraulic lightness compared to the cable. As for feel, I found the friction point a little closer in with the hydraulic clutch but not drastically different.

The one place I did find a difference was the starts. Both are fine but if you make the change it may take a few goes to get your starts dialled in. Being someone who is not really a clutch abuser I was comfortable with either set up but can see how the hydraulic clutch may be less fatiguing on the hand being that bit lighter. Both setups are fine and easy to adapt to.

Words | Mat Boyd

Photos | Mitch Lees